Aerospace Component Finishing

In aerospace engineering, surface integrity is paramount. Every component must perform under extreme conditions — high stress, temperature fluctuations, and corrosive environments — without failure. At R & R Polishing Ltd, we deliver specialist metal finishing services designed specifically for the aerospace sector, ensuring optimal component performance, longevity, and regulatory compliance.

Our Technical Expertise:

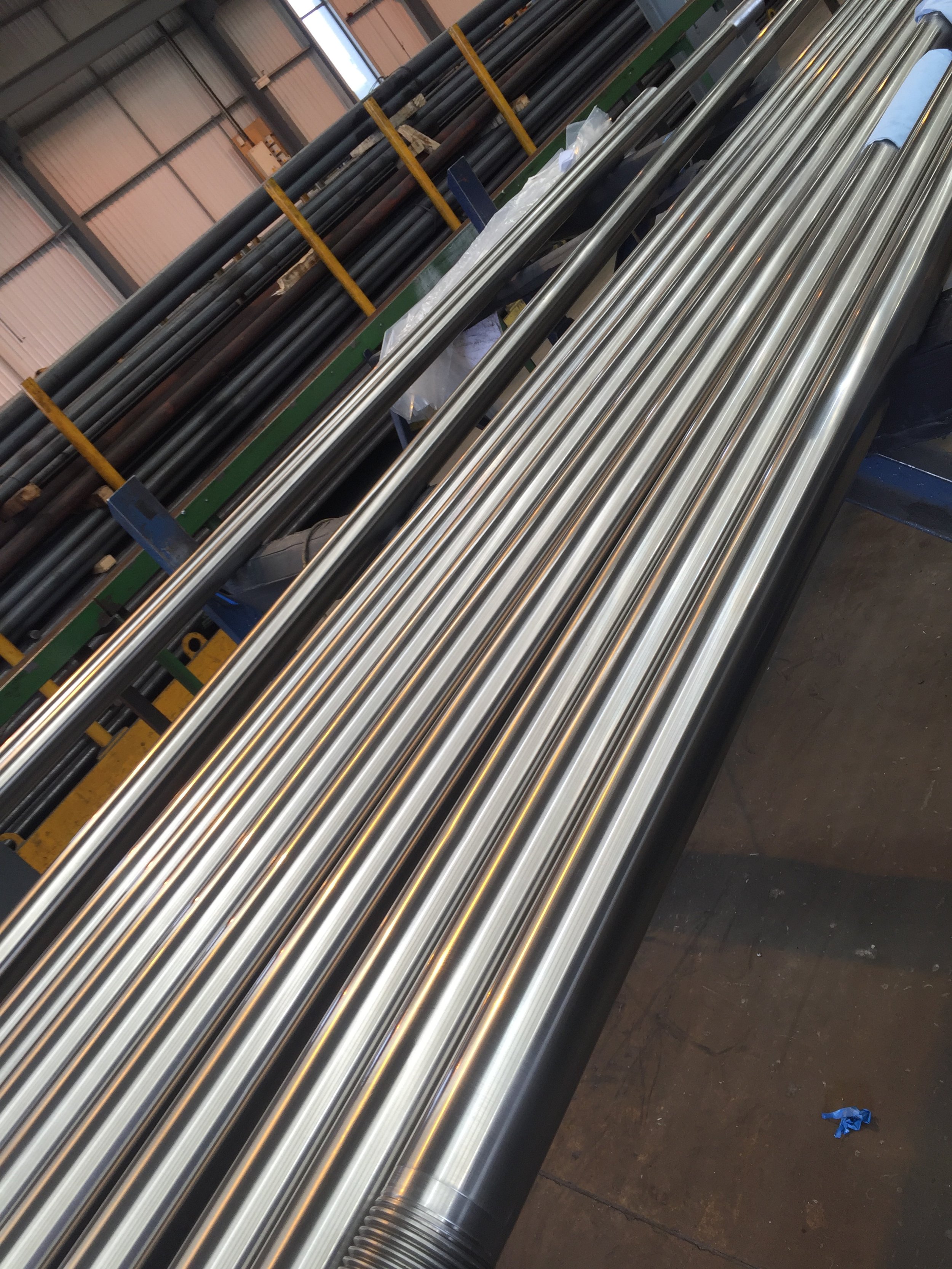

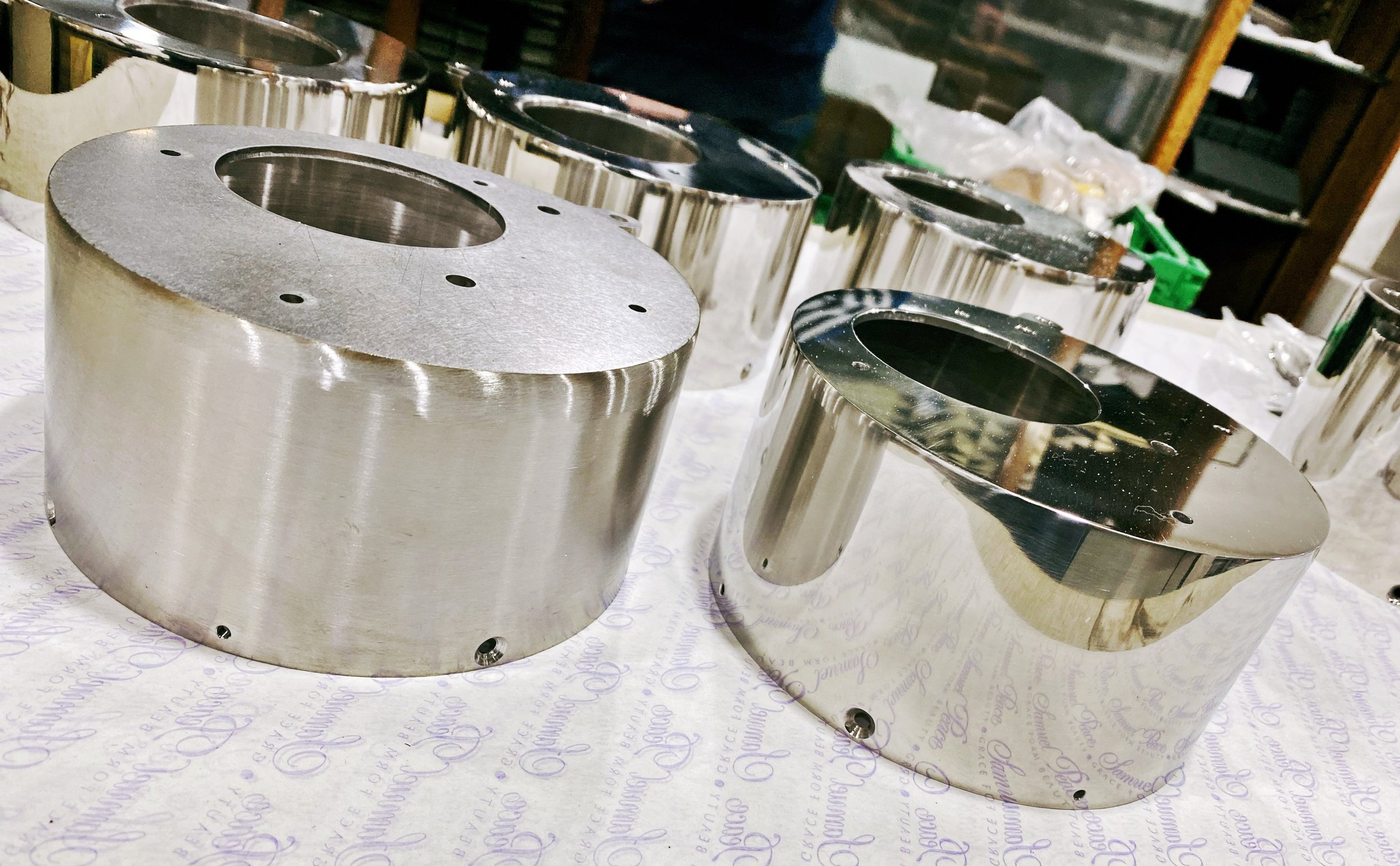

We work across a range of aerospace-grade metals, including Austenitic and Martensitic Stainless Steels, Duplex Steels, and specialist alloys. Our advanced polishing, buffing, and surface conditioning processes achieve superior Ra (Roughness Average) finishes, improve fatigue resistance, and enhance corrosion protection — all without compromising critical dimensions or tolerances.

Our services support:

Structural and load-bearing components

Precision fittings and fasteners

Hydraulic system elements

Actuation hardware and aerospace sub-assemblies

The Critical Role of Surface Finishing:

Surface roughness, residual stress, and micro-defects can all dramatically impact the performance and lifespan of aerospace parts. Controlled, high-precision finishing reduces crack initiation points, optimises aerodynamics, improves wear resistance, and ensures maximum reliability in service.

Why Choose R & R Polishing Ltd:

Precision Engineering Standards: We achieve strict surface finish specifications (Ra, Rz), maintaining tight dimensional tolerances critical for aerospace assemblies.

Performance-Enhancing Processes: Our finishing improves fatigue strength, corrosion resistance, and operational efficiency — essential for mission-critical applications.

Rigorous Quality Control: Every project undergoes meticulous inspection and quality assurance, traceable throughout the process.

Flexible Capacity: From small-batch prototyping to large component runs, we offer both in-house and on-site finishing solutions.